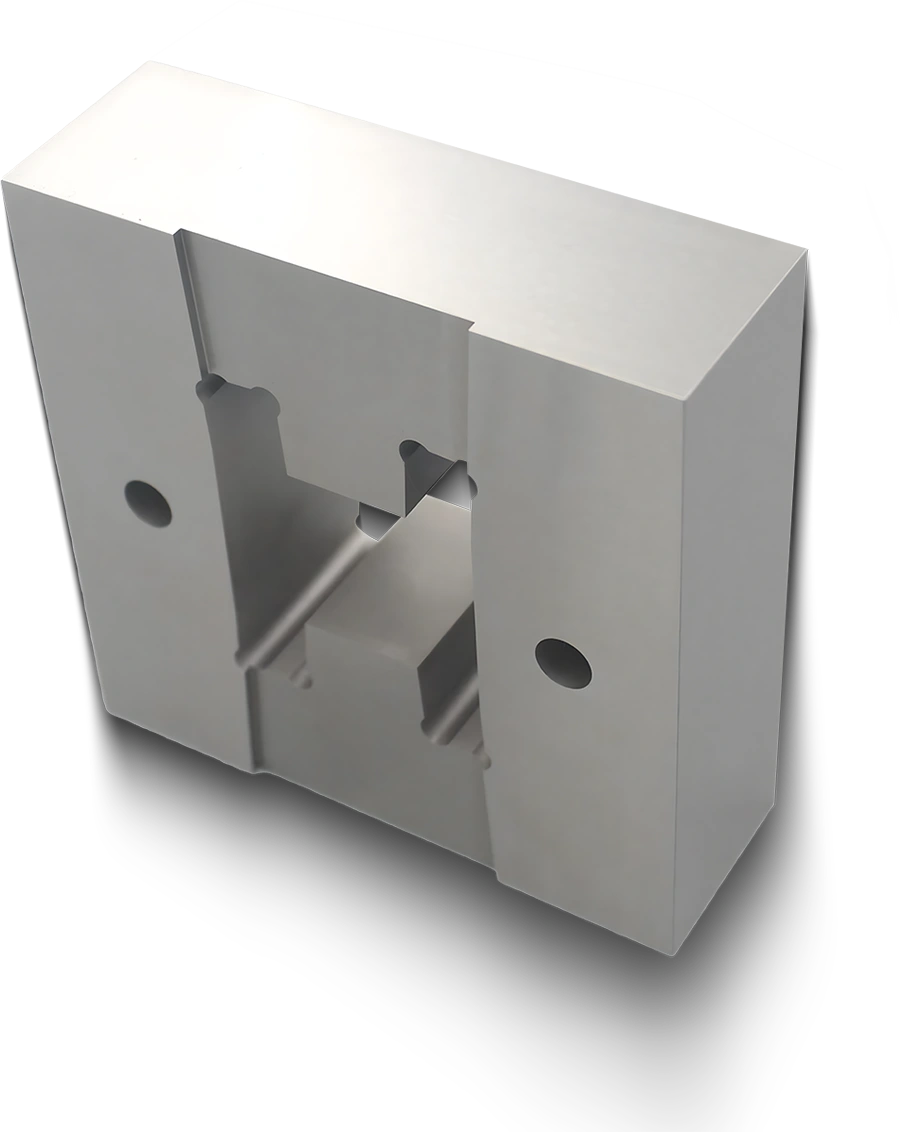

The EDM service (Electrical Discharge Machining) of First Mold has the ability to manufacture durable molds. Moreover, it can also conduct precise processing on parts with deep grooves or rounded corners, providing high-quality solutions for various industrial needs.

Firstmold widely uses EDM in mold making, which makes our mold processing technology intelligent, automatic and efficient. In addition to the mirror EDM and double-ended EDM, we also have many high-precision imported EDM, which can better perform precision machining on molds.

FirstMold typically uses a electric discharge machine to finish the components of a mold. We also use these machines to machine the following parts.

Industria automobilistica

45# Steel

7 minutes

Bearing Industry

Bearing Steel

5 minutes

Construction Machinery Industry

Gray cast iron

4 minutes

Gear Industry

Acciaio legato

9 minutes

Split Gear Parts Industry

Acciaio al carbonio

5 minutes

Split Gear Parts Industry

Acciaio al carbonio

4 minutes

Numbers of EDM

Fine and uniform surface with no pinholes

R-value as low as 0.1, almost vertical angle

Automation and no workpiece wear

Iscrivetevi per ricevere offerte speciali e omaggi.

[sibwp_form id=1]

Email: [email protected]

Partenariati - Informativa sulla privacy - Termini e condizioni - Mappa del sito - Copyright 2025 © First Mold. Tutti i diritti riservati.

Informativa sulla privacy - Termini e condizioni - Mappa del sito

Copyright 2025 © First Mold. Tutti i diritti riservati.

Copyright 2025 © First Mold. Tutti i diritti riservati.