Home / PBT Injection Molding

PBT Injection Molding

High strength and stiffness PBT (Polybutylene Terephthalate) plastic solution

- Excellent electrical insulation for electrical and electronic components

- Glossy appearance for visible parts

- Rapid and precision injection molding cycles

FirstMold's PBT Injection Molding Capabilities

FirstMold possesses comprehensive knowledge and experience in PBT injection molding, including various modified PBT materials. Our mold designers have extensive capabilities in product analysis and understanding user requirements, combined with precise mold CNC machining and on-site production management skills, enabling us to create products that exceed your expectations in PBT injection molding.

Applications of PBT Injection Molding

Although PBT does not feel as smooth as ABS and has poorer light transmission compared to ABS, PBT has carved out a niche in the keycap market against ABS keycaps thanks to its superior durability and oil resistance.

Automotive & EV

- Connector systems

- Sensor housings

- Junction blocks

- Headlamp bezels

- Door handle mechanisms

- Electrical mirror adjusters

- Thermostat housings

Electrical

- Circuit breaker components

- Switchgear parts

- Relay casings

- Plugs and sockets

- Light switch components

- Mounting bases

- Housings for electrical meters

Electronic

- PCB mounts

- Bobbin and coil formers

- Electronic housings requiring EMI/RFI shielding

- Keyboard keycaps

- Electronic gears and cams

- USB connectors

- Control knobs

Home Appliances

- Control panels and buttons

- Coffee machine components

- Blender bases and gears

- Air conditioner control housings

- Range hood filters and frames

- Humidifier tanks and caps

- Fan blades and housings

The modifications of PBT mainly include flame-retardant PBT, glass fiber-reinforced flame-retardant PBT, and glass fiber-reinforced PBT. PBT is commonly blended with PC to form alloys used in automotive parts, with PC/PBT often utilized for car bumpers. Additionally, modified PBT can be used for car window motor housings, motorcycle motor parts, and automotive transmission gearboxes.

PP

PE

PC

PVC

ABS

PA

POM

PBT

PMMA

PEEK

PBT Products Quality Assurance

The quality of PBT plastic fabricated products is inseparably linked to the quality of the raw materials used. We have stable suppliers with whom we’ve cooperated for over a decade, and we can provide quality inspection reports for any raw materials. We can also purchase from suppliers you specify and provide proof of purchase.

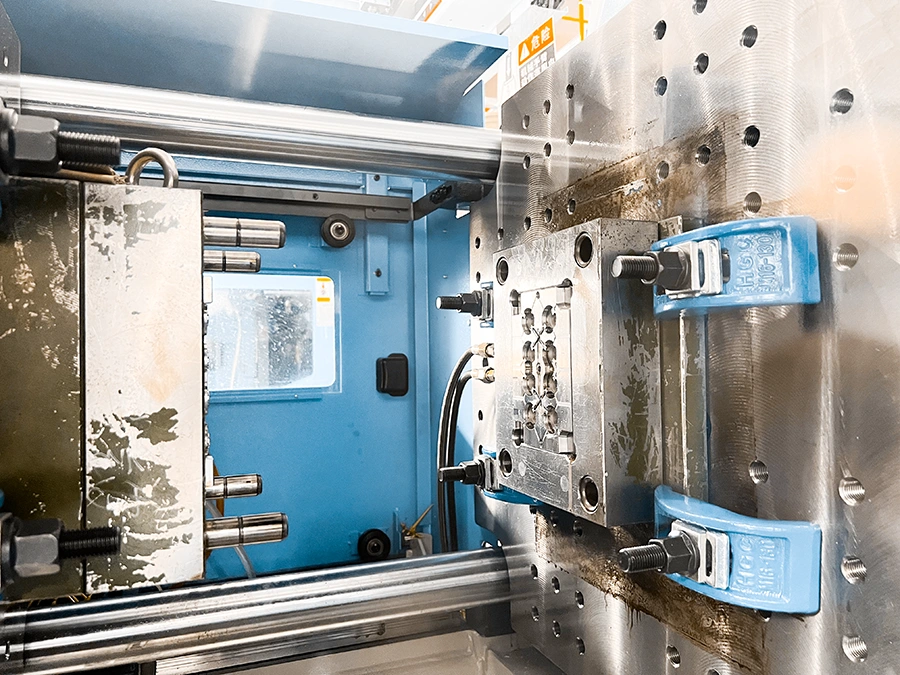

Advanced Mold Testing

FirstMold conducts mold fitting and mold polishing for every set of molds and performs mold testing using precision CNC machines, precision injection molding machines, and mold fitting machines.

In-Process Quality Checks

FirstMold implements 6S management on-site, promptly addressing any issues that arise at each stage. Injection molding production also includes timely spot checks, along with immediate preventive measures and quality control adjustments.

Final Inspection and Testing

Comprehensive final quality inspections are conducted using professional testing equipment, including coordinate measuring machines (CMM), height gauges, moisture analyzers, pressure gauges, and color controllers, to ensure the utmost quality.

Advantages of ABS injection molding

Through the various features of ABS injection molded parts, we can easily understand the multiple advantages of ABS injection molding.

- Durability and Precision: ABS injection molded parts provide the necessary impact resistance, dimensional stability, and precision required for components like dashboards and bumpers, durable casings and intricate components.

- Aesthetic Versatility: These parts can be finished to a high-quality appearance, suitable for toys and appliances that require an attractive look, as well as healthcare devices where functionality combines with user-friendly design.

- Cost-Efficient Production for High-Volume Industries: The ease of processing and recyclability of ABS make it ideal for industries like construction and packaging, where cost efficiency and the ability to produce large quantities of durable, precise parts are critical.

According to statistics, ABS material has the highest usage rate in all injection molding projects at FirstMold.

PBT Injection Molding Cases

This case shows the insert molding process to produce drone remote control housing from a Chinese plastic component manufacturing factory

This study shows the molding manufacturer's capabilities to manufacture perfect fuse holder base parts with precision injection molding.